Iveco Daily 4x4 - Brake Problems

Brake Problems

If you have any brake problems, in the first instance present your vehicle to Iveco, but also please let us know so other owners are made aware and hopefully to help prevent a possibly serious or fatal accident

The main dissapointment with the Iveco is the poor Braking, and overheating brakes especially when towing on the long mountain descents of Great Dividing Range.

HEADS UP for potential new Owners....

These vehicles are not suitable for Australian Conditions, The Trucks are not required to pass ADR testing because they are made compliant on the back of EU certification , Truck speed limits in most of Europe , including Germany & Italy are 80kmhThe second issue is the Daily 4x4 was advertised as having vented front rotors, the Iveco spec sheet & workshop Manual say they are Vented and they are falsely certified in Australia under RVCS as having vented front rotors . They do NOT have vented rotors.

In some cases Iveco have paid to fit vehicles with VARI Vented Rotor Upgrade Kit ( Recipients have been made to sign Non Disclosure agreements - AKA gag orders - This information has come to me from within the Industry - not from recipient of gag order )

Owners Incidents

Thunderbolts Way NSW, 9 Dec 2013

The brakes issue first reared its ugly head for me in our own truck, After a 7km 12% steep downhill stretch towing the Caravan on Thunderbolts Way (Baxters Ridge Trail) found the downhill engine braking of the Iveco to be zero, and the Brakes to be down right dangerous. On this steep winding road there is no where to pull over to let the brakes cool and with the green Transfer case Lever forward and in low gear we had trouble holding the rig back and with engine over-revving. Luckily the hill levelled out before I lost all brakes. We had to stop at the first opportunity for an hour to let the brakes cool, and our van is only 1.8T and has its own heavy duty 12" x 2.5" electric drum brakes too !! The front brakes got so hot on the truck that the powder coating on the rims melted causing the wheel nuts to loosen, something I did not notice until a few days later.

Broome - Willare road WA. 30 May 2015

This video demonstrates how bad the brakes are, Not only do they overheat on mountain highways, they just dont stop the truck when you really need to. Believe it or not this is a full panic crash braking event, if you listen carefully you can hear the caravan brake lock up, one wheel then the other , but the truck itself did not even have ABS register.

The cow did not survive. Any typical 4x4 would not have come off quite as good as the Iveco, having suffered only a bent bullbar support bracket, but any other 4x4 would also have stopped in time to avoid the impact !!

"Glow in the Dark" brakes, December 2016

And this is what they really look like after coming down from Mt Baw Baw Vic. Photo courtesy of Phil Marsh,Original (non vented) Iveco brakes, glowing red hot, The brakes on the truck actually caught fire, Plastic wheel nut caps melted, Even with improved cooling of EVA Alloy rims

No need to mention Phil has now fitted the Aftermarket BHSS Vented Rotors.

Mt Perry QLD, 6 June 2015

From Dave McNee, Dual Cab 4x4."Well now I definitely know my rear brakes aren't working. Today I got caught out on a 3km downhill range outside of Mt Perry In Qld which didn't have any warning signs, I had already come through about 30 Ks of wInding hills and had been cautious with the braking, so when I entered this steep section my brakes would of already been warm. Once I realised how steep this was I slowed back to 30 but could not hold it so increased caravan braking and dropped another gear which did nothing. I was on off brakes for the rest of the downhill run and it got progressively worse. I was now holding our speed at 40 with the van brakes but they were fading. I had run out of options!!My mate behind me told me on the 2 way my brakes were burning. Once we got to the bottom I pulled over and we inspected all the brakes, the rear drums were cold, yes cold!! My van weighs 3 ton and I had a ton in the back. Something needs to be done about this as it is simply a tragedy waiting to happen. I had my wife and 3 kids in the truck and I didn't let on what was happening. It scared the shit out me. Talking with Iveco on Tuesday. Not happy, actually still in shock I think."

Despite what the Iveco literature will have you believe the front Rotors are SOLID - Non Ventilated discs. 22mm thick x 297mm dia .

The Specification sheet says they are Ventilated, The Workshop manual shows a picture of Ventilated rotors, and Iveco Power Parts show Ventilated, Even the SCAM.it website has literature to the effect that the front rotors are Ventilated. But the brakes on ALL and EVERY 55S17W ever delivered to Austrtalia have NON-Ventilated front rotors.

Beware the brakes overheat easily on long mountain highway descents (as found on the East Coast of Australia), but the brakes are usually no problem in offroad situations.

Iveco Australia Specs Iveco power parts 55S17W Shop manual PDF from SCAM trucks website

Also note for a routine brake rotor grind, or disc replacment the swivel housing needs to be dismantled, King pins removed and $600 UNIT bearings destructively pressed out . Not a DIY Job. A pair of these SOLID rotors is around $1500 . Similarily sized Ventilated Landrover or Toyota Rotors are about $120 a pair. What might normally cost around $500 - $800 for a routine front brake service on any other 4x4 or truck, involving rotor and pad replacment may well cost you in the area of $2500 - $3000 for this vehicle, due to unbelivebly expensive consumable parts pricing and a ridiculously complicated rotor replacment procedure. You can look forward to that every 80 - 100,000km and that for woefully crap brakes.

In a meeting I had at Iveco Dandenong in 2014 I was given assurance from Daily product manager, Iveco Australia, that it is a priority that the new model 55S17W will have the same Vented Rotors as the new 2WD daily and they think they will be able to be retrofitted to our existing trucks. The new Euro6 model 4x4 recently released in Australia still has the Non ventilated rotors.

This is also despite the fact that The Iveco ADR Compliance Number (37140 on compliance plate) as on the RVCS Database is listed as having Ventilated Front Rotors (last checked March 2017)

http://rvcs-prodweb.dot.gov.au/perl/37140_1135308_RVD_10Jun2015143127.cmd

Aftermarket Front Rotor upgrade

I had an idea to replace the Standard Iveco (Perrot) 297mm Solid rotors with 350mm disc ventilated rotors. My idea as proof of concept involved machining down the old rotor to become a Mounting Hat for a 12 bolt flat rotor, but technically for road use a new alloy mounting hat needs to be machined. At left a original rotor is shown, At right is my photoshopped image using Flat rotor as used on performance vehicles. The image is showing scallops in the outside of the drive hub to allow the rotor mount flanges to pass over it. As well as having brakes that should operate as they are expected to on a modern vehicle, this retrofit will also allow rotor replacment without dismantling the swivel housing nor the need to disturb the wheel bearing.

June 2015, Giovani Orso is the first lucky owner to have his 4x4 Daily retrofitted with the new brakes manafactured by VARI Race Brakes. Not only does this new Ventilated Rotor fit over the outside of the drive hub, but it uses the original (modified) caliper and pads.

Image 1 shows level of dissasembly required to service the Original Iveco Rotors, For the upgrade it only needs to be done once

Image 2 & 3 Shows comparison , Original Non Vented - With new Brakes

Image 4 Shows quality of this conversion - with CNC Caliper adaptor

Image 5 = Inside view of assembled housing

and 3 images below of assembled housing

September 2015, - Yee Haa... We have brakes. The Braking on the truck is still not perfect but a HUGE improvment, with little fear of brakes catching fire or melting as they do with original equipment.

Iveco Australia continue to be outwardly in denial of the poor brakes on their 4x4. Behind closed doors we know it is a different matter.

The Vehicle (with standard brakes) passes ADR testing, so in my opinion the issue is more to do with ADR protocols, Why should a manafacturer make brakes better than they need to be anyway?? hmm .....safety would be one reason!

Here we have the Vented rotor kit fitted to our truck.

My Brakes were cooked during the white knuckle ride down Thunderbolts Way, Iveco Brisbane "Inspected" the brakes and said they were OK after that event, afterward we had one look at my brakes and the Caliper sliders were stuck, slider rubber cooked and dust seals burned away, This would not have affected the clamping force of the caliper, but certainly unroadworthy so rebuilt my calipers.

.... the last photo just as a comparison to remind us of the standard front brake during a pad swap at 45,000km.

The truck now does indeed pull up in about 2/3 the distance of before, if enough force (and size 11 work boots) is applied on the pedal the ABS will only just engage on bitumen, that was absolutely inpossible before.

Vari Big brakes, and replacement rotors avaliable from VARI Race Brakes .

Feb 2017 .....Rear Disc Brakes Project

IN 2014 the Australian Product manager responsible for Iveco Daily 4x4 told me they would ideally like to fit rear disc brakes to these vehicles but he told me for practical purposes it would be impossible for Iveco to acheive.

The supplier of the rear axle Carraro list the HS 8.09 as having optional Disk brakes (see PDF) , enquiries direct to Carraro lead to a dead end, apparantly there is no Disc option, if there is they dont make it avaliable except to manafacturers.

The Reality ..... Retrofitting Non-Iveco ventilated DISC brakes to the rear.

Having searched through Catalogues of thousands of listings I found one inexpensive and commonly avaliable 325 x 30mm vented rotor that will fit the Iveco 4x4 rear hub, (with some minor machining).

The rotor is from the rear of a US built 4x4 truck with spares commonly avaliable in Australia.

Unfortunatly the vehicle which this rotor belongs to uses the drum-in-rotor style handbrake system, which can not be easily adapted to the Iveco 4x4 because the ABS tone ring occupies the space inside the 'drum' , but luckily there is also one readily avaliable and inexpensive caliper that will fit our chosen rotor. The '85 Cadillac Eldorado rear caliper is about the only possibility because as well as being a hydraulic caliper (with single 53mm piston) it also has a cable handbrake mechanisim.

The original Iveco Handbrake fits the GM caliper with the addition of an adaptor tube. These so called GM 5.5 "metric calipers" are commonly used on 4x4 and motorhome rear disc conversions in USA, but do have a reputation for being difficult to adjust. However I found adsjustment simple and installation straight forward.

Images at right, ..... 1/ Adjust from PCD 170x8 to 170x6,

2/ As per usual Iveco style, the a spanner in the works, the rear bearing / hub nut or lockring is torqued to 600Nm and needs a special keyed tool

Images at left, ..... 1/ Adjust outer diameter of rear hub ,

2/ mock up Caliper Bracket mounted to Iveco backing plate flange & original ABS mount & sensor

Below are a series of 5 video clips using 3 cameras, Dashcam with speed readings, roadside camera . and external truck mounted camera,

The Truck now stops as good a typical passenger car and is how it should be from the factory. Compare the modified brakes with stopping effort of standard brakes with the Iveco vs Cow clip at the beginning of this page

Center Diff Lock open, ABS active, dirt 80kmh 44m stopping distance , (normal driving mode)

CDL open, - ABS deactivated , dirt 82kmh 32m stopping distance

Center Diff Lock engaged, (ABS deactivated) dirt 82kmh 32m stopping distance

ABS activated, 95kmh 45m stopping on bitumen (normal driving mode)

ABS deactivated , 96kmh 40m stopping on bitumen,

Brake Pipes and Correction Valve

A number of these trucks have had brake line failures, the metal brake lines along the chassis have a habit of popping out of their plastic clips and are free to rub on bodywork etc, I have cable tied my lines into various clips.

A number of these trucks have had brake line failures, the metal brake lines along the chassis have a habit of popping out of their plastic clips and are free to rub on bodywork etc, I have cable tied my lines into various clips.

In several cases the brake pipes above the rear diff has also broken, there is rumour of a National Recall, yet I have heard nothing from Iveco. The pipe from the rear load proportioning valve needs a stress relief loop, the bracket holding the valve vibrates causing the pipes to fatigue, crack and brake off

One owner, John from Goondiwindi, told me that his pipe broke twice and he temporarily replaced it with a flexible hose from a Cortina. Most brake repair centers will replace the metal pipe with flexible hoses.

Whilst on the subject of the Load Proportioning Valve, or as Iveco call it, Correction Valve, well that is a total anachronisim, there is absolutely no need for this valve on a vehicle fitted with ABS. The valve itself is quite primitive and has no place on a modern braking system. In fact it makes the bad brakes on this truck even worse by reducing pressure to the rear brakes, no matter which way it is adjusted.

In fact the image of the new Euro6 Daily 4x4, at left, shows that the Penny has finally dropped (or should I say Lira) and the new truck does not have the Correction Valve. image thanks to euro6 ... casa-trotter.com

I already took this rear load proportioning valve off my truck because I realised the rear brakes were never working, and this after Brisbane Iveco checked my brakes and gave them the "all clear" . Firstly, again, there is no need for this device with ABS, and secondly now I have no concerns about my rear brake pipes failing from fatigue fracture.

Front Pads

From early on I was not too impressed with Iveco ServicingBefore any modification I had a 40,000km Service at Rocklea Iveco (Brisbane) and one of the Issues I had with that service is they did NOT check the brakes, I specifically asked the Service Manager to check the brakes as they had overheated twice & I suggested the fluid would need flushing .

I assumed it was done & not until I took a wheel off 900km later in Sydney did I notice the pads were stuffed, then I checked the invoice & there was no indication that they checked the brakes nor flush the fluid. That borders on negligence. There is no way the brakes would last till the next service so I ordered new pads and wear sensors from Newcastle and did the job myself at 45,000km.

The pictures show

1/ the stuffed pads in the right caliper

2/ how the Brembo caliper opens to change the pads,

3,4/ two images of the old vs new pads,

5/ damage to the friction material from overheating, starting to break up.

6/ left caliper photo shows new pads fitted

I complained to Rocklea Iveco and finally recieved an email response "I reviewed your service job-card personally today, and can confirm that your brakes were checked as part of this service. No work was required, because the brakes were all in good order.."

You can see yourself from the photos of the cooked and thin pads above that the brakes were not in "good order", this was about 1500km after Iveco "checked" the brakes

Great Truck, a pity about the brakes, this bloke seems to know what he is talking about,

must be a breakdown in communication as it don't seem to apply to the Design Team and Service Staff of the 4x4 Daily!!

...... over to Iveco Tom, on Brakes

Rear Brake wear

I thought I should carry a spare set of rear brake shoes (yes they are drums, not discs) but almost fell over upon finding the price of one set, over $1500 You can buy new shoes to refit a complete semi trailer for less !! ( when it comes time I'll be getting my old shoes relined insted.)

I thought I should carry a spare set of rear brake shoes (yes they are drums, not discs) but almost fell over upon finding the price of one set, over $1500 You can buy new shoes to refit a complete semi trailer for less !! ( when it comes time I'll be getting my old shoes relined insted.)Its possible to check the rear brake wear by removing one of the rubber caps on the brake backing plate, (not the bottom hole - thats the adjuster port). The photo shows my linings at 45,000km , there is still heaps of meat - in fact it looks like the have not had any use at all , as it turns out the reason why they are not worn at all, is because in my opinion, of the un-necessary factory fitment of a Load Proportioning valve over ABS brakes.

Rear brake shoes, part number 2996480

- No other vehicle I know of has these shoes, only the 55S17W and SCAM, so there is no aftermarket supply of them - they are $1500 from Iveco, Im thinking they are made of Titanium with solid gold rivets ??? (NOT), There is absolutely nothing special about these shoes, they are only 11" dia. I found some on Alibaba - for $3-$10 Each, but minimum order is 10,000 units. Just take a moment to have a look at the rear shoe in the picture, click on it to enlarge it. Show any spare parts guy the picture and ask him how much - I'm guessing he will say about $75.00 a set or 4 (2 per each rear wheel). How the hell can Iveco in their right mind charge $1500, Bend over and grab your ankles .... What a rip off, - go to any brake specialist they will reline the brakes shoes with bonded friction material. Even from Vexi, UK they are RRP £869.41 = $1734.13 AU (not including shipping)

Exhaust Brake

The Iveco Daily is the only Truck in its class that does not come standard with an Exhaust Brake. Even the Mercedes Sprinter, a lighter class vehicle has an exhaust brake as original equipment. From 2012 the Fuso Canter uses 4P10 Engine, (4P10 is the Mitsubishi designation of same FPT - F1C engine in the Daily ) has an exhaust brake as standard. Iveco has no exhaust brake, will not option an exhaust brake. Iveco threathen to void your warranty if you fit an exhaust brake on the Daily.

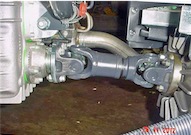

Above images show the Exhaust Brake on the 4P10, just behind the single VGT,

rear view without engine pipe clearly shows the exhaust brake butterfly valve

Iveco will not give me a valid reason as to why they will not allow an exhaust brake, they acknowedge the same engine in the Canter has one so any argument that an exhaust brake will harm your turbo or engine is not valid. The Fuso Canter comes with single VGT or twin turbos - both versions have exhaust brake.

The Daily 4x4 wheel brakes are not that great to begin with, Despite the Iveco documentation it has front NON-ventilated discs & rear drums (even the 2WD Daily has ventilated front rotors and rear discs) and once you are loaded up and have a trailer or caravan behind you the downhill braking is dangerous. Coming down the Toowoomba Range or Thunderbolts Way which is 7km of 12% highway, with no chance to stop or pull over to let the brakes cool can easily end in disaster. Because of the EGR valve which does not close at zero throttle the engine braking on these trucks is non existant and they will run away from you very easily, to be managed you have to be in a much lower gear and descend much slower than other traffic which can cause a hazard to following vehicles (who may also not have enough brakes to avoid hitting you).

The kit includes microswitches for clutch and brake pedals , I also wired in a realay to disengage the cruise control when the Exhaust brake is energised.

I used a traditional gear lever mounted switch rather than the kit supplied, dash mounted toggles switch

The kit includes microswitches for clutch and brake pedals , I also wired in a realay to disengage the cruise control when the Exhaust brake is energised.

I used a traditional gear lever mounted switch rather than the kit supplied, dash mounted toggles switch

Most factory fitted exhaust brakes are mounted on the back of the turbo. Aftermarket exhause brakers are usually further back in the exhaust pipe, which could cause a few error code issues.

The DPF Delta P sensor may be damaged from overpressurisation, this is overcome by fitting 12V pneumatic cutoff valves in the DPF lines.

Iveco gurus have told me the EGR closes at zero throttle but this is actually not the case, if the exhaust brake is operated whilst the EGR valve is still open it could also bring up ECU error codes. A Quantum DPF / EGR Delete which will give long term benefits to your engine and better fuel economy too solves the EGR errors, and gives better natural engine braking as a bonus.

The Australian RVCS Compliance of the Euro 5 Iveco Daily 4x4 shows it is locally certified as a Euro 4 (the DPF may be able to be removed legally - Euro 4 Daily is not fitted with DPF)

The Lambda sensor also needs to be relocated to behind the Exhaust Brake to stop high Oxygen concentration level fault code during exhaust brake activation.

Telma Electro Retarder

"Iveco offers the Telma electro retarder as an option on the Daily 4×2 range.

The electro retarder is installed in the prop-shaft between the gearbox and rear axle. It is in effect an electric brake that can be applied using a hand controller and helps to reduce the speed of the vehicle by slowing down the prop-shaft – basically having the same effect as engine braking but with much more power."

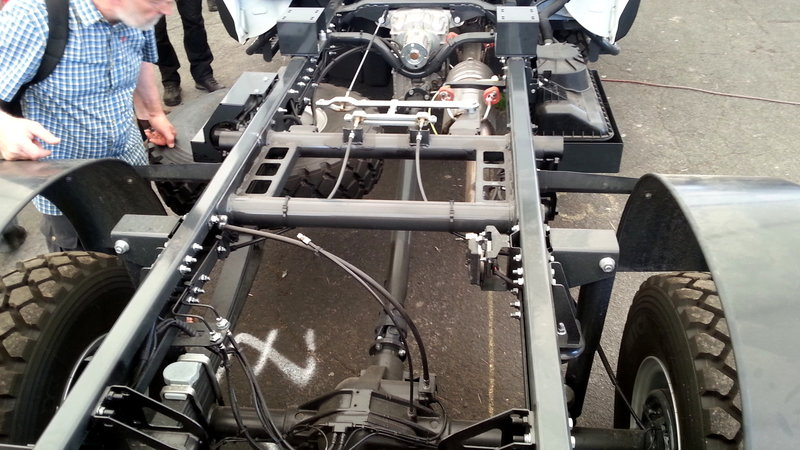

Images showing Iveco experimental attempt at Installing Telma Retarder on 55S17W,

So wrong in so many ways, No ground clearance, bad propshaft angles

- an example of bad engineering design and bad execution.

Marcus and Julie Tuck having just completed a 18 month African expedition in their 4x4 Daily have made it a priority to find a solution to the poor braking issue before continuing with their world tour.

Having been back in UK for a mere matter of weeks Marcus has already done what Iveco have been unable to do.

Read all about it !!! Compleat Idiots Guide to Iveco Daily 4x4 55S17W (buy the book :)

Iveco Daily Links